Eyewash Station Inspection Templates

Eye Wash Station Inspection Requirements Employee safety is an important responsibility that extends beyond simply having the right equipment somewhere in the building. 4k video downloader mac serial lookup number. When an accident happens, safety equipment needs to be accessible and operating properly in order to provide the type of emergency treatment capable of avoiding serious injury. The Occupational Safety and Health Administration (OSHA) refers employers to The American National Standards Institute’s (ANSI) standard Z358.1 specifically to address minimum selection, installation, operation, and maintenance requirements. The following checklist is a summary of the provisions of ANSI Z358.1-2014 relating to emergency eyewashes: Checklist Inspection Frequency: Activate all eyewash units at least weekly (Section 5.5.2). Inspect all eyewash units annually for compliance with the ANSI Z358.1 standard (Section 5.5.5). Location: The eyewash safety station must be located within 10 seconds, approximately 55 feet, from the hazard. The station must also be located on the same plane as the hazard and the travel path to the eyewash must be unobstructed.

If the hazard includes strong acids or caustics, the emergency eyewash should be located immediately adjacent to the hazard and a professional should be consulted for further recommendations (Section 5.4.2; B5). Identification: The area around the eyewash station must be well-lit and the unit must include a highly visible sign (Section 5.4.3). Water Temperature: Tepid water (60-100°F) is delivered to the eyewash (Section 5.4.6; B6). The valve actuator is easy to locate and easy to activate for the user (Section 5.2). The safety station washes both eyes simultaneously and the water flow allows the user to hold the eyes open without exceeding 8” above the spray heads (Section 5.1.8). Spray heads are protected from airborne contaminants.

Covers are removed by the water flow (Section 5.1.3). The eyewash safety station delivers at least 0.4 gallons of water per minute for 15 minutes (Sections 5.1.6, 5.4.5).

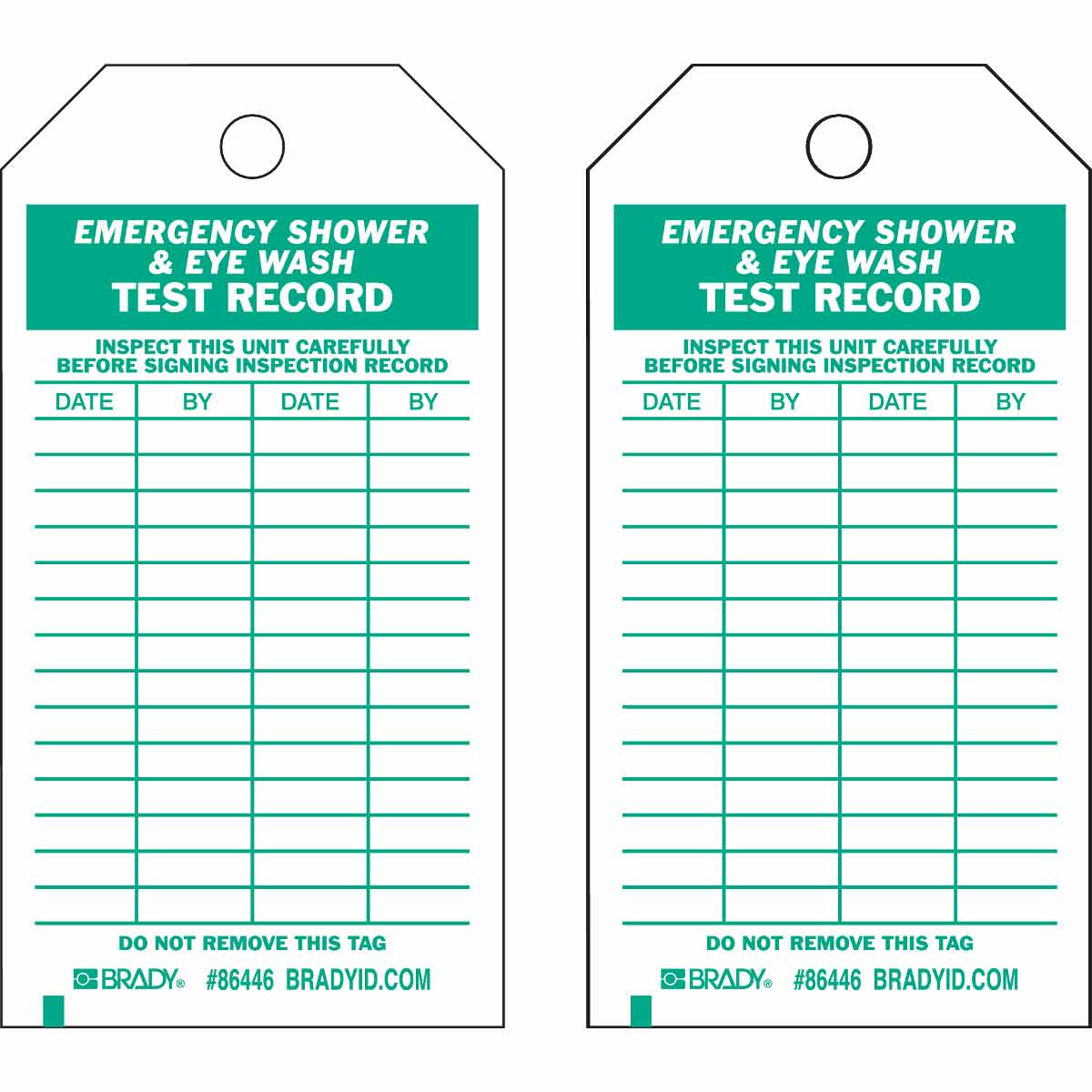

Emergency eyewash and safety showers are required in areas where personnel can come into contact with hazardous materials that could harm eyes or skin. All eyewash and shower stations must be inspected weekly and the results logged (see. Emergency Eyewash Test Record Form). Plumbed Eyewash Stations/. 2, Eye Wash Station Inspection Record, Year: 3. 4, Week # / Date, Initials, Comments, Resolution.

Water flow pattern is 33-53” from the floor and at least 6” from a wall or nearest obstruction (Section 5.4.4). Hands-free stay-open valve activates in one second or less (Sections 5.1.4, 5.2). Eyewash Direct is the proven source for all your eyewash station and safety shower needs.

Eyewash Station Inspection Log Template

Shop today and take advantage of our online resources, personal & expert advice, and our huge selection of the products your facility requires.